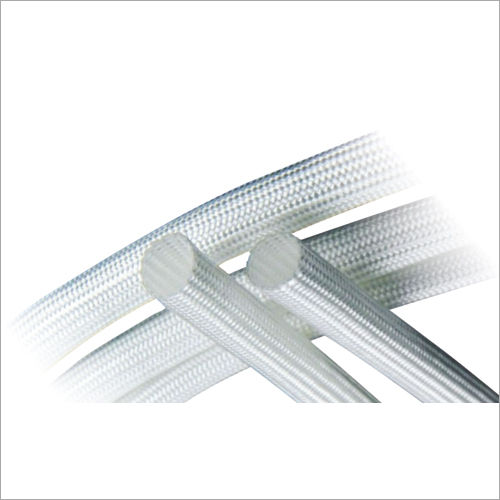

Glass Braided Silicon Coated Fiberglass Sleeving

2000 INR/Meter

Product Details:

- Size 3.00-25.00mm

- Product Type Glass Braided Silicon Coated Fiberglass Sleeving

- Usage Industrial

- Color Black And White

- Material Fiberglass

- Click to View more

X

Glass Braided Silicon Coated Fiberglass Sleeving Price And Quantity

- 2000 INR/Meter

- 300 Meter

Glass Braided Silicon Coated Fiberglass Sleeving Product Specifications

- 3.00-25.00mm

- Black And White

- Fiberglass

- Industrial

- Glass Braided Silicon Coated Fiberglass Sleeving

Glass Braided Silicon Coated Fiberglass Sleeving Trade Information

- 300 Meter Per Day

- 7 Days

Product Description

| Brand | Kiran |

| Size | 3.0mm to 25mm |

| Thermal Class | Class "H" |

| Thermal Temperatures | -60 DegreeC to +180 DegreeC |

| Voltage Rating | 600 Volts |

| Color | Black & White |

| Heat Aging | 1440 hours at 235 DegreeC Without Dielectric Change |

| Flammability | Self-extinguishing(Ul 1441 & Nema) |

| Dielectric Strength | 4000 Volts - 7000 Volts |

| Ul Grade | Grade "A" - VW 1 |

| Model Number | Kirasri 180 VPI |

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Fiberglass Sleeving' category

|

KIRAN UDYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS